Customer Services

Copyright © 2025 Desertcart Holdings Limited

🔥 Weld Like a Pro, Wherever You Go!

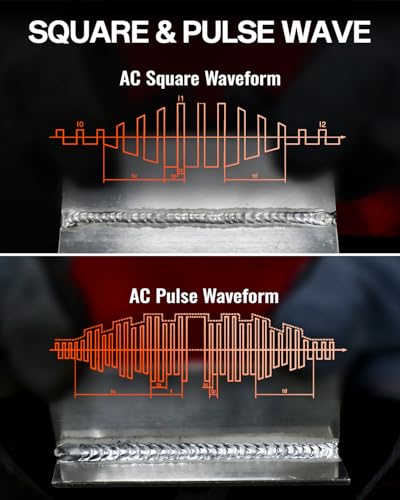

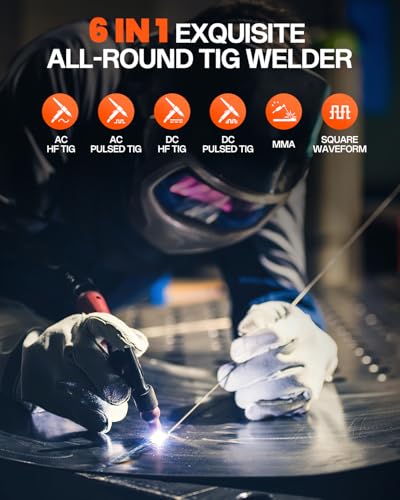

The HITBOX TIG Welder AC/DC 200A HBT250P is a compact, versatile 6-in-1 welding powerhouse designed for professionals and serious DIYers. Featuring pulse and square wave technology, HF start, and precise AC/DC TIG controls, it excels at aluminum and steel welding with minimal spatter. Lightweight and equipped with dual cooling fans and a digital display, it offers advanced safety and ergonomic control modes, making it ideal for workshops or on-site jobs. Backed by a 2-year warranty and expert support, it’s the affordable choice for mastering multi-metal welding.

| ASIN | B0BRZT75YM |

| Batteries Included? | No |

| Batteries Required? | No |

| Best Sellers Rank | #726,425 in Automotive ( See Top 100 in Automotive ) #908 in TIG Welding Equipment |

| Customer Reviews | 4.2 4.2 out of 5 stars (823) |

| Date First Available | February 7, 2023 |

| Included Components | TIG WELDER |

| Item Weight | 26 pounds |

| Item model number | HBT250P |

| Manufacturer | HITBOX |

| Package Dimensions | 19.29 x 14.65 x 10.83 inches |

| Part Number | HBT250P |

| Power Source | ac_dc |

| Size | HBT250P |

| Style | 6 IN 1 AC/DC TIG |

C**Y

Good Value AC/DC Tig

For the price of this tig welder you really can't go wrong, it does AC and DC tig along with stick. I did not do any stick welding with it yet. Ran the machine on a few parts and it welded flawlessly. It comes with everything you need for tig welding except a regulator, tungsten and cylinder of argon, it does not come with a stick electrode holder. This welder uses the smaller 25mm dinse twist lock connectors, it has high frequency start with pulse, it is a point type HF start. The 17 series torch works well, it a euro stye and accepts all common 17 series parts for the head. The fans run all the time but not too loud, the inface is standard for most all tig machines so setting it up is easy. I don't know if they make a pedal for this welder but might be a good add on, either way the trigger on the torch with up and down slope works well. Its small and compact and would make a good bench or machine to load up to take on-site. It 230V single phase only, you cannot plug into a 115v wall socket, I would assume it would do fine on a generator with a 30amp 230v output. The max amps is 200 and welding 1/4 aluminum is about as thick as it will weld for smaller parts, the power does seem legit as I do have a video of a bung being welded in 1/4 6061. Fit and finish is excellent, I was really surprised how good the arc was, for doing turbo pipes, exhaust and small parts this should work great. AC tig for doing aluminum on a budget is the real benefit to this machine. ***Update, this little tig machine continues to put in the work, compared to some of my other much more expensive tig machines it is super handy to move around the shop for quick tack ups and repairs.

A**R

Brand new to this, very early days, but so far so good.

Brand new to TIG welding here, and I'm not any kind of pro welder at all. Self-taught (i.e, poorly-taught)/home-jobber. I have a MIG I picked up a couple of years ago that's served me well for home-tasks and 'hot-metal gluing' stuff together. My welds are not pretty, I have minimal skill, but I can stick stuff together and it holds. I'm not building race-car roll-cages, or other mission critical stuff. We're talking 'stitch up cracked lawnmower deck' or 'build an angle-iron wood-rack' .. the kind of low-risk stuff that's easy enough to just 'do' w/out much of a plan. I wanted a TIG box that could do AC for aluminum simply b/c I think it would be neat to be able to weld aluminum. My MIG welder does DC-TIG and does it well enough from the couple of tries I made with it when I first got the MIG box. But, for anything steel I needed to weld, the MIG-mode has been fine, and is easier IMHO. So, TIG... new ballgame. This welder has a high-freq start, which I can say works great (again, as appears to a novice). My MIG's DC-TIG is 'lift-arc', which requires more skill than I have. I have not stuck the electrode once with this AC/HF-start... it starts the arc a solid 10mm above the work. I have no idea if that's too high, prob is... again.. I'm a novice at this. I just was experimenting with how high/easy it would start an arc. Above about 10mm or so.. it was less reliable... maybe up to 13mm... don't quote me, but to me, it seems plenty high-enough. I've only spent a day at this point just laying down beads on scrap, and my 'beads' are not pretty.. but 'fusion beads', to me, seem fine. There's a lot to adjust for a newbie: rise, peak A, base A, +/- balance, fall, pre and post-flow... pulse mode settings. I worked through adjusting each setting a few different ways just to see if they had any effect and I can say, for me, I noticed differences in each setting. So, these settings are not 'vapor ware'... they all do something. I have the foot pedal as well, and I think this is the way to go. I mean, I know 'pro' TIG setups usually have a pedal, but since this box doesn't come with it, you have to buy it separately. Oddly enough, I got mine months ago to use for my MIG welder as an experiment (partial success)... but now that I have this TIG box, I reconfigured it to work with this new welder as originally intended. So, the pedal definitely makes it nicer to use, imho. The button on the included TIG torch appears to be on/off only. There's no obvious 'rocking' feature that would indicate it controls amperage. This is prob fine for learning, and maybe that makes it easier to learn with... I don't know. I have the pedal, so I'm only ever going to use the pedal. Again, the welder has settings for rise-amps and fall-amps which taper the amps at the start of the weld and at the finish.. this is ostensibly to help pre-heat and prevent cratering. Just repeating what the manual claims... I don't know enough to know this independently... but it sounds logical. The pulse mode is interesting. This will 'pulse' the arc from 1 to upwards of 300 times a second automatically. I won't claim to know why this feature exists, but I see it on a lot of 'better' machines, so I don't think it is a gimmick. I was playing around with it, and set it to 2, and it definitely only does a pulse every 1/2 a sec. I ramped it to 10, definitely way more pulses/sec. Higher than that and it really buzzes them out. I'm guessing the application for this must be on thin metals or something you're trying not to pour a lot of heat into. The gas hose... ugh.. this is by far the weak-point of the machine. It has a nipple for the output and not a B-size inert-gas connection. It comes with a stiff vinyl hose and two hose clamps. My argon bottle has B-size connx, so I had to find a barb-to-B adapter to connect up to one end of the hose. The problem -there- is that the hose is not 1/4" and doesn't work with 1/4" barbs. I imagine it is metric, so maybe its like 8mm... no idea... didn't measure. My hacky work-around for now is I wrapped my 1/4" adapter in a layer or two of good electrical tape. After hose-clamping this vinyl hose on... tests for gas-tightness passed the 'soapy-water' test. I'm going to find out what metric size hose-nipple I need and order one, then make a small pigtail-hose that has a female B-size coupler on one end, and hose-clamp the pigtail to the machine's nipple. Then I can use my regular gas-hose and not this goofy vinyl hose. I may later figure out if I can swap out the gas nipple with a B-size connecter directly to the machine and eliminate this pigtail hack. I don't want to open up the machine yet b/c it is still under whatever warranty it comes with, in addition to the Amazon 30day/whatever return-period. If the pigtail works well enough, that's fine for now. The stinger for stick-welding it comes with is, well... very cheap... as is the ground-clamp. I have a nicer ground clamp from my MIG that fits this TIG box (DINSE connectors). So, the stinger and ground clamp that came with the TIG box are prob never gonna be used. I don't stick-weld, but if I did, the stinger that came with my MIG box is better quality and I would just use that one. So!... don't buy this box b/c you think the components are going to be great. The TIG torch, I think, is fine in my zero-experience opinion. I can say it seems comfortable enough, has a bit of 'swivel' action at the end to help with hose-bind. It is not top-quality stuff, but of the 'accessories' that come in the box, it is the nicest (the others being the ground-clamp and ARC-stinger, which are very 'iffy' looking). The attraction here is the TIG box itself and the fact that it does AC, which at this price point/day-in-time makes it one of the most affordable such boxes if you want to do aluminum TIG. You also get a pulse mode function which may not have all of the options of high-end boxes, but having pulse-mode at all at this price, to me, seems like a bonus. I would've been plenty happy just getting AC mode (with some adjustment on AC balance even). The consumables you get are 'enough' to get going. You can 2 tungstens (red), one is 1/16 and the other looks to be maybe 1/8 or 3/16? You get the correct 'brass' to use either size in the TIG torch. I don't think there's any spares of these items... but again, this is enough to get up and running. You do get a few extra nozzles.. 6's and 8's... I don't recall any other sizes. These are what you'd expect... just ceramic gas nozzles. You can get packs of TIG consumables/nozzels/brass on Amazon, should probably do that. I do not know what 'brand' these consumables are patterned after... the brass is a collet-style, if that helps. I am sure it is going to be patterned after some name-brand, just don't know what that is off-hand myself. I have zero to say about durability as I've only had the box 2 days, and only used it a few hours at this point. If it blows up, I will definitely update this review. Conversely, if I have no trouble with it, I'll also update this review.. it may be some months before either happens.

R**S

TIG200 is NOT AC!

THIS IS NOT I REPEAT NOT AN AC TIG MACHINE!!!!!!! I had thought I hit the jackpot when I was doing my research and everything on the Hitbox TIG200. Everything said that it was ac capable and could TIG weld aluminum. Seeing it was only $120 I jumped on it and was super excited. I have a MiG welder with a spool gun for aluminum but isn’t capable of ac TIG. But the welder performs and functions well. It’s not the welders fault that someone put false and/or misleading information about it. I’m going to keep it regardless.

C**S

Superb Welding Machine

As an avid hobbyist welder, I've been thoroughly impressed with the HITBOX TIG Welder AC/DC. This machine delivers on its promise of versatility and performance. First off, the AC/DC capability is a game-changer for me. Whether I'm working on aluminum sheets or delicate joints, the ability to switch between AC for aluminum and DC for other metals ensures I get clean, precise welds every time. The pulse function further enhances control, allowing me to manage heat input effectively, which is crucial for welding thin materials without warping. Setting up the machine was straightforward, thanks to the intuitive controls. It supports a range of welding techniques, including TIG, Stick, and MMA, which makes it a versatile tool for different projects. The IGBT technology ensures stable arc performance, even when dealing with challenging welding conditions. In terms of build quality, the HITBOX welder feels solid and durable. The construction is robust, and the cooling system keeps everything running smoothly even during extended welding sessions. I particularly appreciate the compact design, which makes it portable enough to transport to move around my workshop without hassle. Overall, the HITBOX TIG Welder AC/DC with Pulse has exceeded my expectations. It's a reliable workhorse that offers exceptional value for its price point. Whether you're a seasoned welder or just starting out, this machine will definitely enhance your welding capabilities and make your projects more enjoyable and professional-looking.

B**R

Impecc ... able to do whatever I want with this excellent tool.

T**G

I bought this after previously buying a DC only Hitbox TIG welder, but now wanting to be able to weld aluminum. Initially I was skeptical of how well an amazon welder would work, but I was actually really surprised, they work great. For stick welding, the inverter technology welds smoother than transformer welders I've used in the past. I learned TIG welding on a Hitbox machine, so I can't say I've used any others to compare, but I have no complaints, it was a good machine to learn on. It's got a wide range of settings and features, so I don't think I will outgrow this machine. That's the good, here's the bad: The leads are quite short, and maybe a little light. The stick welding stinger feels really cheap, and the contacts actually rusted. I believe they're only copper coated steel. But both of these things can be easily upgraded if you need to. The fan is always on, which is probably better for the machine, but can be a bit annoying. This machine also only works on 220V. Again, probably better for the machine, but does lack the versatility and portability of being dual voltage. I can't say anything at this point, but the long term reliability and quality might be an issue. I wouldn't run a business with this, but I think for a hobbyist it's perfect. All in all, it does what it's supposed to, and is pretty amazing for the price.

A**O

El soldador inverter ha demostrado ser una herramienta eficiente y versátil para llevar a cabo trabajos de soldadura. Una de las características destacadas del soldador inverter es su tamaño compacto y ligero. Esto facilita su transporte y manejo, permitiéndote llevarlo a diferentes lugares de trabajo sin dificultad. Además, su diseño ergonómico y cómodo de sostener hace que sea fácil de utilizar durante largos periodos de tiempo. En cuanto a su rendimiento, el soldador inverter ha mostrado una excelente capacidad de soldadura. Su tecnología inverter proporciona una corriente estable y precisa, lo que resulta en soldaduras limpias y de alta calidad. Además, cuenta con ajustes de potencia y control de amperaje, lo que te permite adaptarlo a diferentes tipos de materiales y espesores. Otra ventaja del soldador inverter es su eficiencia energética. Este tipo de soldadores consumen menos energía en comparación con los soldadores convencionales, lo que te permitirá ahorrar en costos de electricidad a largo plazo. En términos de seguridad, el soldador inverter suele estar equipado con funciones de protección contra sobrecalentamiento y sobrecarga. Estas características garantizan un uso seguro y evitan daños en el equipo durante trabajos intensivos. En resumen, el soldador inverter es una herramienta confiable y eficiente para trabajos de soldadura. Su tamaño compacto, rendimiento de alta calidad y eficiencia energética lo convierten en una opción popular entre profesionales y aficionados. Sin embargo, es importante tener en cuenta tus necesidades específicas y realizar una investigación exhaustiva para elegir el modelo adecuado que se adapte a tus requerimientos y presupuesto.

V**R

Gör det den ska

S**A

👍

Trustpilot

3 weeks ago

2 weeks ago