Customer Services

Copyright © 2025 Desertcart Holdings Limited

⚡ Cut Sharp, Last Long, Own the Mill!

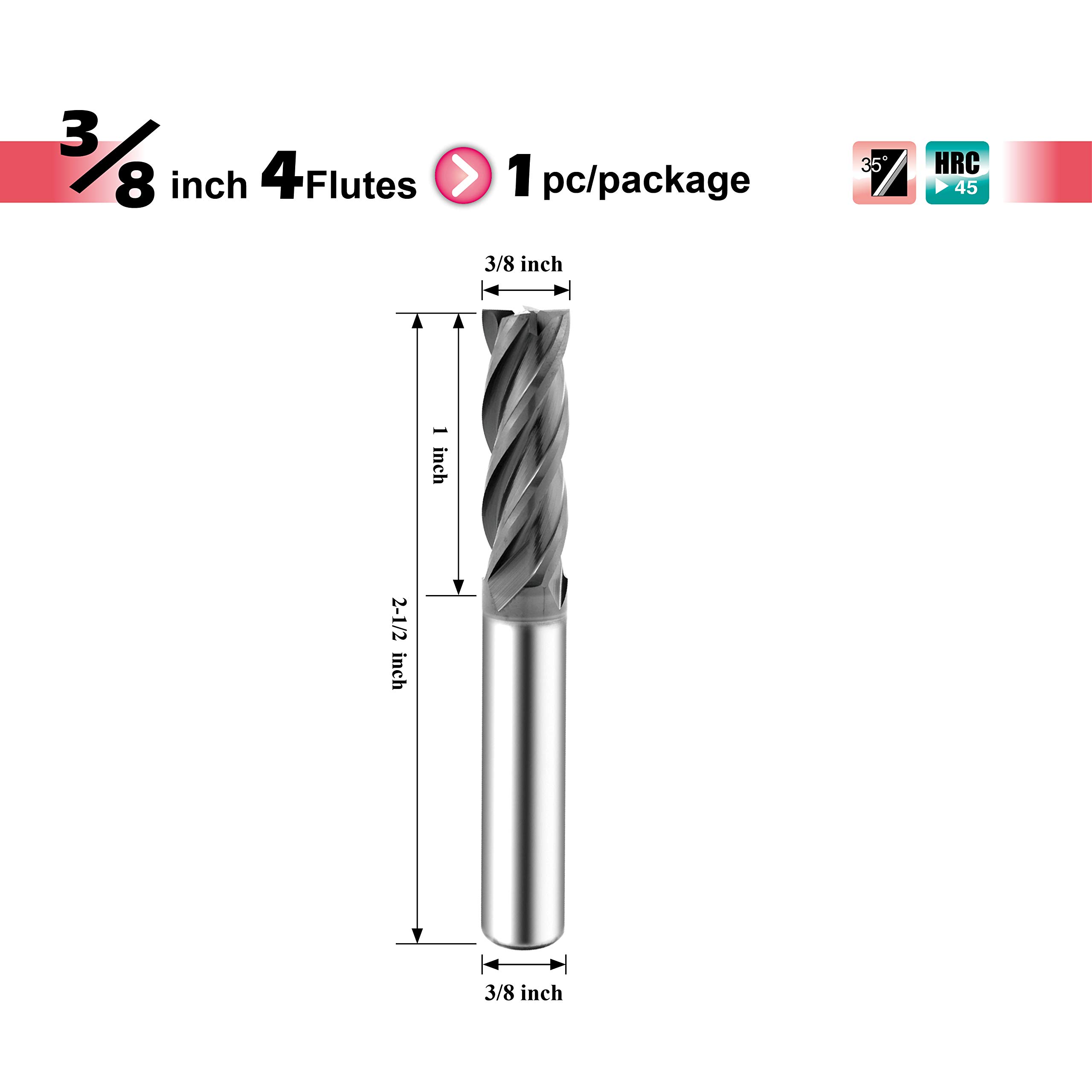

The SPEED TIGER Micrograin Carbide Square End Mill features a 4-flute design with a precision tolerance of ±0.02mm, crafted from durable micrograin carbide. Its advanced AlTiBN coating delivers exceptional heat resistance, making it ideal for milling a wide range of steels including hardened and alloy varieties. Perfectly suited for both professional machinists and serious DIYers, this 3/8" end mill combines high performance, longevity, and value in one sharp, reliable tool.

| ASIN | B07FSLS7X3 |

| Best Sellers Rank | #8,568 in Industrial & Scientific ( See Top 100 in Industrial & Scientific ) #1 in Square Nose End Mills |

| Brand Name | SPEED TIGER |

| Customer Reviews | 4.5 out of 5 stars 2,046 Reviews |

| Cut Type | square end |

| Cutting Diameter | 9.53 Millimeters |

| Cutting Length | 2.5 Inches |

| End Cut Type | Square End |

| Finish Types | AlTiBN |

| Item Dimensions L x W | 2.5"L x 0.38"W |

| Item Height | 0.1 centimeters |

| Item Weight | 50 Grams |

| Manufacturer | SPEED TIGER |

| Material Type | Carbide |

| Number of Cutting Edges | 4 |

| Number of Flutes | 4 |

| Shape | Square |

| Size Name | 3/8 in |

| Tolerance Held | Precision |

| Unit Count | 1.0 Count |

N**J

Works As Advertised

Sharp and true. Does what I expect from a carbide end mill.

B**N

Great product, worth every penny

Bought these for a hobby. Received them and like that they are packaged individually, thus helping keep them sharp. Used them on a firearm building project and only eneded up using one. But stayed sharp and met the needs of what I was using it for. If your are a hobbyist and looking for some high quality milling bits with out having to pay a premium these are the ones to go to.

W**D

Worked great for engraving hardwood

I used these bits in a Foredom jewelry engraving tool along with some StayMax Metal hollow number guided to engrave numbers in my beer flights project. Then I mixed powdered turquois in resin to make these numbered holes.

R**!

Decent bit but do snap fairly easily. See comments.

UPDATE: I upped my rating from 2 tp 4 stars. Customer service was very helpful and responsive. They actually contacted me when they saw my original review. I found that my spindle speed was too slow. Obviously it depends on the material but these bits have to be spun pretty fast and the depth and feed rate must be shallow and slow as well. My mill only spins at max 2800rpm. So I spun it at 2800rpm and took a more shallow cut along with a slow feed rate and these things cut pretty decently. I assume they would work better at an even faster spindle speed. They are still very brittle and will snap if you apply to much side pressure. Overall they did the job I needed them for. Item came packaged well and they looked good. I ordered the 1/16th size and these things snap at the slightest pressure. I almost messed up my project so I had to discontinue using them due to them snapping so easily. I tried another set I had and had no issue.

A**R

Good for tool steel

Great endmills and a great price. I use them on hardened tool steel and had no issues.

P**1

Awesome

I keep buying these to replace my hss end mills. They are awesome, and cut like a hot knife through butter. I cut a lot of 416 stainless and these make hss look like junk. Almost no burrs to file off even after cutting a keyway in a threaded shaft. Definitely a must.

D**Y

Great end mill

Held up very well cutting 304 stainless even under sub-optimal feeds and speeds, which were the limitations of my CNC. I tried another (different brand) popular carbide end mill on the same job / stock subsequently for comparison. The other end mill ground itself into a needle due to intense heat. But this Speed Tiger came out of the same job intact and still sharp.

K**8

Best bang for your hard earned money

I wasn't expecting to much out of these end mills due to the price. Let me tell you these .25 end mills are worth more. I used 1 endmill and ran it nonstop on my Bridgeport for 9 hours straight. After the piece was completed I checked the endmill and it was as when I first put the endmill in. I will be buying A LOT more of this brand. Now to test their .375 roughing bit tomorrow. Update: These end mills are way better then I ever gave them credit for. I had to make a few die molds for our production line. Material was 4140 for the tie downs and D2 for the actual dies. I was able to cnc mill everything with a single end mill. I used only air to cool the work piece and clear the path.

Trustpilot

2 days ago

5 days ago